PCD type automatic controller

|

Proportional automatic tension controller PCD-120B When winding/unwinding paper or film, this equipment varies the excitation voltage according to the roll diameter, automatically providing constant tension to a powder clutch/brake. Diameter variation is automatically detected using a proximity switch, simplifying configuration. This high performance controller uses a microcomputer which allows storage of a number of media profiles, and also automatically stores the last output voltage in the event of a power failure. |

|

Features

| Hunting will not occur during automatic operation due to an open loop control.

| The integrated microcomputer can store settings for up to 99 different types of material.

| Since we store the last output voltage in the in the event of a power failure, operation can be resumed by simply restoring the power source.

| In addition of 24V output, there is switchable 0-10V output which can be used to drive an AC servo motor.

Operating principle

Figure 1 shows an example of how the PCD-120B can be used on unwinding equipment. The thickness of the material, the initial radius of the feed roll, and the radius of the takeup roll are set in advance and after the appropriate output voltage is input on the dial, it begins to unwind. The decrease in unwinding diameter is detected through shaft rotation and the electromagnetic powder brake's input voltage is decreased accordingly to maintain a constant material tension. Figure 2 shows a series of control patterns

● About the rotation detector

The rotation detector outputs one pulse per shaft rotation. The controller receives this pulse and begins counting at when winding commences(material thickness x roll shaft rotation number). The current radius is calculated from the initial radius and the number of rotations, after which the excitation current of the electromagnetic powder clutch/brake is adjusted proportionally.

Dimensional outline drawing

|

Specifications

| Type | PCD-120B | PCD-120BM | Display function | OUTPUT VOLTAGE | Display on MONITOR | |||

| Method | Winding diameter proportional control by roll diameter rotation detection | OUTPUT CURRENT | ||||||

| Application | Winding/Unwinding switchable | ROLL DIAMETER | ||||||

| Power | AC100/110V,200/220V,Switchable,50/60Hz | DATA NO. | ||||||

| Output current | 0〜3A PWM Control 0〜10V(10mA) Analog output |

TAPER RATIO | ||||||

| Control resolution | About 0.5mm | AUTO | Indicator (red) | |||||

| Response frequency | Less than 500Hz | STOP | Indicator (red) | |||||

| Setting function | Start roll radius | 3 digits 010〜999mm | 3 digits 010〜999mm (Note1) |

DATA INPUT | Indicator (red) | |||

| Stop roll radius | 3 digits 000〜999mm | 3 digits 000〜999mm (Note1) |

START ROLL SIZE | Display start radius settings | ||||

| Material thickness | 3 digits 0.01〜9.99mm | 3 digit 0.001〜0.999mm (Note1) |

STOP ROLL SIZE | Display stop radius settings | ||||

| Taper rate | 2 digits 00〜99% | 2 digits 00〜99% | MATERIAL THICK | Display material thickness settings | ||||

| Structure | Steel plate, wall and protective type | |||||||

| Accessory | Proximity switch for rotation detection 1 set | |||||||

| Weight | 5.5kg | |||||||

| Paint color | Case Munsell 5Y8/0.5 PanelP2-1007 | |||||||

| Compatible clutch/brake | Electromagnetic powder clutch/brake Less than POC/POB/PRB-20type (Note 2) | |||||||

(Note)1

Up to 99 different data can be set

(Note)2

With the powder clutch/brake larger than type 40, the control is possible by the connection of operation amplifier PS-6.0A.

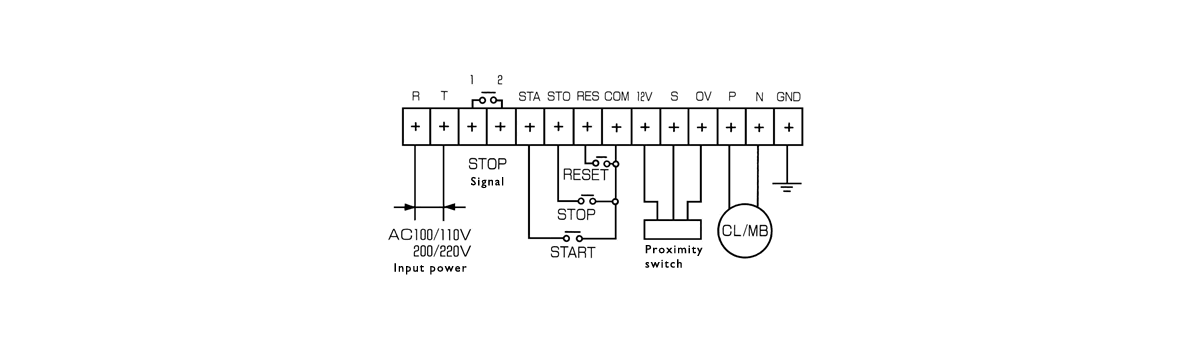

Input terminal connecting diagram